Ore-Sorting

What is Ore-Sorting?

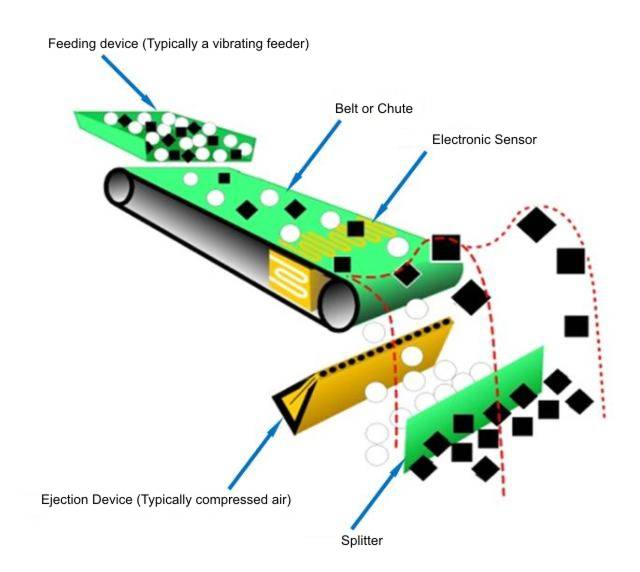

Ore-sorting is a process for upgrading mineral bearing rock at large particle sizes, typically between 250mm and 10mm (1 to 4 inches) and

involves evaluating the mineral content of individual rocks as they pass through a sensor then separating them into Accept and Reject fractions,

based on pre-determined selection criteria.

X-ray scanners that either measure density or actual copper and molybdenum grades can be used to select material for processing.

Ore-Sort Video - General

Ore-Sort video - Tungsten

Why Does Ore-Sorting Work on CuMo?

Geologists have known for years that the grade at CuMo is contained in narrow stockwork veins,

with the number and width of these veins controlling the grade. The more veins and/or thicker the veins the better the grade.

Geological zones vary from 0% to 40% of the material containing the grade.

The example below contains a drill intersection on the edges of the molybdenum core zone.

Use the radio buttons to turn the sorting on and off.

The section from Hole 11-59 from 1630 to 1640 feet assayed 0.175% Mo

Approximately 10% of the interval contains the actual molybdenum veins which are dark grey to black in the picture.

The box length is 2 feet long. Breaking it into to 2 to 3 inch pieces is done to simulate primary crushing.

Sorting would initially identify the ore (red - 22.5%) within the interval and that would be mill feed, secondary sorting would identify the stockpile (yellow - 30.5%),

and remaining material is waste (blue - 47%). This would result in a grade of 0.583% Mo for the ore, and 0.134% Mo for the stockpile.